Amabhere ehhabhu lezimoto ayesetshenziswa kakhulu ngamapheya erola eline-tapered noma amabhola amabhola. Ngokuthuthuka kobuchwepheshe, iyunithi yehabhu lamasondo emoto isetshenziswe kabanzi. Amayunithi okuthwala ihabhu aya ngokuya asetshenziswa futhi asetshenziswa, futhi manje asethuthuke esizukulwaneni sesithathu: isizukulwane sokuqala sakhiwe ngamarowu amabili ama-angular contact bearings. Isizukulwane sesibili sine-flange yokulungisa i-bearing ku-raceway yangaphandle, okungase kube lula ukubeka umkhono wokuthwala ku-axle futhi ulungiswe nge-nati. Ukwenza ukunakekelwa kwemoto kube lula. Isizukulwane sesithathu seyunithi yokuthwala ihabhu ukusetshenziswa kweyunithi yokuthwala kanye ne-anti-lock brake system ABS coordination. Iyunithi yehabhu yakhelwe ukuthi ibe ne-flange yangaphakathi kanye ne-flange yangaphandle, i-flange yangaphakathi iboshwe ku-drive shaft futhi i-flange yangaphandle ihlanganisa yonke into. Amabhere ehabhu agugile noma alimele noma amayunithi ehabhu angabangela ukwehluleka okungafanele nokubizayo kwemoto yakho emgwaqeni, noma alimaze ukuphepha kwakho.

Sicela unake amaphuzu alandelayo ekusetshenzisweni nasekufakweni kwama-hub bearings:

1. Ukuze uqinisekise ukuphepha nokuthembeka okuphezulu, kutuswa ukuthi ngaso sonke isikhathi uhlole ama-hub bearings kungakhathaliseki ukuthi imoto indala kangakanani - uqaphele noma yiziphi izimpawu eziyisixwayiso zangaphambi kwesikhathi zokuguga, okuhlanganisa noma imuphi umsindo wokungqubuzana phakathi nokuphenduka noma ukuncipha okungavamile kwesondo lenhlanganisela yokumiswa ngesikhathi sokuphenduka. Ezimotweni ezidonsa ngamasondo angemuva kunconywa ukuthi zigcobe amabhere ehabhu langaphambili kuze kube imoto ifinyelela ku-38,000 km. Uma ushintsha isistimu ye-brake, hlola ama-bearings bese ubuyisela izimpawu zamafutha.

2. Uma uzwa umsindo ovela engxenyeni ephethe ihabhu, okokuqala, kubalulekile ukuthola indawo lapho umsindo uvela khona. Kunezingxenye eziningi ezihambayo ezingase zikhiphe umsindo, noma ezinye izingxenye ezijikelezayo zingathintana nezingxenye ezingaphenduki. Uma kuqinisekiswa ukuthi kungumsindo ekuthwaleni, i-bearing kungenzeka ilimele futhi idinga ukushintshwa.

3. Ngenxa yokuthi izimo zokusebenza zehabhu elingaphambili eliholela ekuhlulekeni kwama-bearings ezinhlangothini zombili zifana, kunconywa ukuba esikhundleni sazo ngamabili ngisho noma i-bearing eyodwa kuphela iphukile.

I-4, ama-hub bearings azwela kakhulu, noma kunjalo kudingeka asebenzise indlela efanele namathuluzi afanele. Ngenqubo yokugcina, ukuthutha kanye nokufakwa, izingxenye ezithwalayo azikwazi ukonakala. Amanye ama-bearings adinga ukucindezela okukhulu, ngakho amathuluzi akhethekile ayadingeka. Hlala ubheka imiyalelo yokukhiqiza imoto.

5. Uma ufaka ama-bearings, kufanele abe sendaweni ehlanzekile nehlanzekile. Izinhlayiya ezinhle ezingena kuma-bearings nazo zizofinyeza impilo yesevisi yama-bearings. Kubaluleke kakhulu ukugcina indawo ehlanzekile lapho ushintsha ama-bearings. Akuvunyelwe ukushaya ukuthwala ngesando, qaphela ukuthi ukuthwala akuwi phansi (noma ukuphatha okungalungile okufanayo). Ngaphambi kokufakwa, isimo se-shaft nesihlalo sokuthwala kufanele futhi sihlolwe. Ngisho nokugqoka okuncane kuzoholela ekungangeni kahle, okuholela ekuhlulekeni kokuqala kokuthwala.

6. Ngeyunithi ephethe ihabhu, ungazami ukuqaqa i-hub bear noma ulungise indandatho yokuvala yeyunithi yehabhu, ngaphandle kwalokho kuzolimaza iringi yokuvala futhi kuholele ekungeneni kwamanzi noma uthuli. Ngisho nendandatho yokuvala kanye nomzila womjaho wendandatho yangaphakathi konakele, okuholela ekuhlulekeni kokuthwala unomphela.

7. Kukhona indandatho kazibuthe eyindandatho yokuvala efakwe isisetshenziswa se-ABS. Le ringi ye-thrust ayikwazi ukuthintwa ukushayisana, umthelela noma ukungqubuzana nezinye izizinda kazibuthe. Zikhiphe ebhokisini ngaphambi kokuzifaka futhi uzigcine zikude nezinkundla kazibuthe, njengamamotho kagesi noma amathuluzi kagesi asetshenzisiwe. Uma la ma-bearings efakiwe, ukusebenza kwama-bearings kuguqulwa ngokubheka iphinikhodi ye-alamu ye-ABS kuphaneli yensimbi ngokuhlolwa kwesimo somgwaqo.

8. Ama-hub bearings afakwe i-ABS magnetic thrust ring. Ukuze unqume ukuthi yiluphi uhlangothi lwendandatho ye-thrust efakiwe, into elula nencane ingasetshenziswa ukuvala unqenqema lwe-bearing, futhi amandla kazibuthe akhiqizwa i-bearing azoyiheha. Ngesikhathi sokufakwa, uhlangothi olunendandatho kazibuthe lukhombe phakathi, ngqo nento ebucayi ye-ABS. Qaphela: Ukufaka okungalungile kungase kubangele ukwehluleka ukusebenza kwesistimu yamabhuleki.

9, ama-bearings amaningi avaliwe, lolu hlobo lwama-bearings empilweni yonke akusona isidingo sokwengeza amafutha. Amanye ama-bearings angavaliwe njengama-roller tapered roller bearings kufanele agcotshwe ngamafutha ngesikhathi sokufakwa. Ngenxa yokuthi ubukhulu bangaphakathi bokuthwala buhlukile, kunzima ukunquma ukuthi ungakanani uwoyela ongawengeza. Okubaluleke kakhulu ukuqinisekisa ukuthi kukhona uwoyela ekuthwaleni. Uma kunamafutha amaningi, lapho ukuthwala kujikeleza, amafutha amaningi azophuma. Umthetho ojwayelekile wesithupha: Ngesikhathi sokufakwa, inani eliphelele lamafutha kufanele lifinyelele ku-50% wokususwa kwe-bearing.

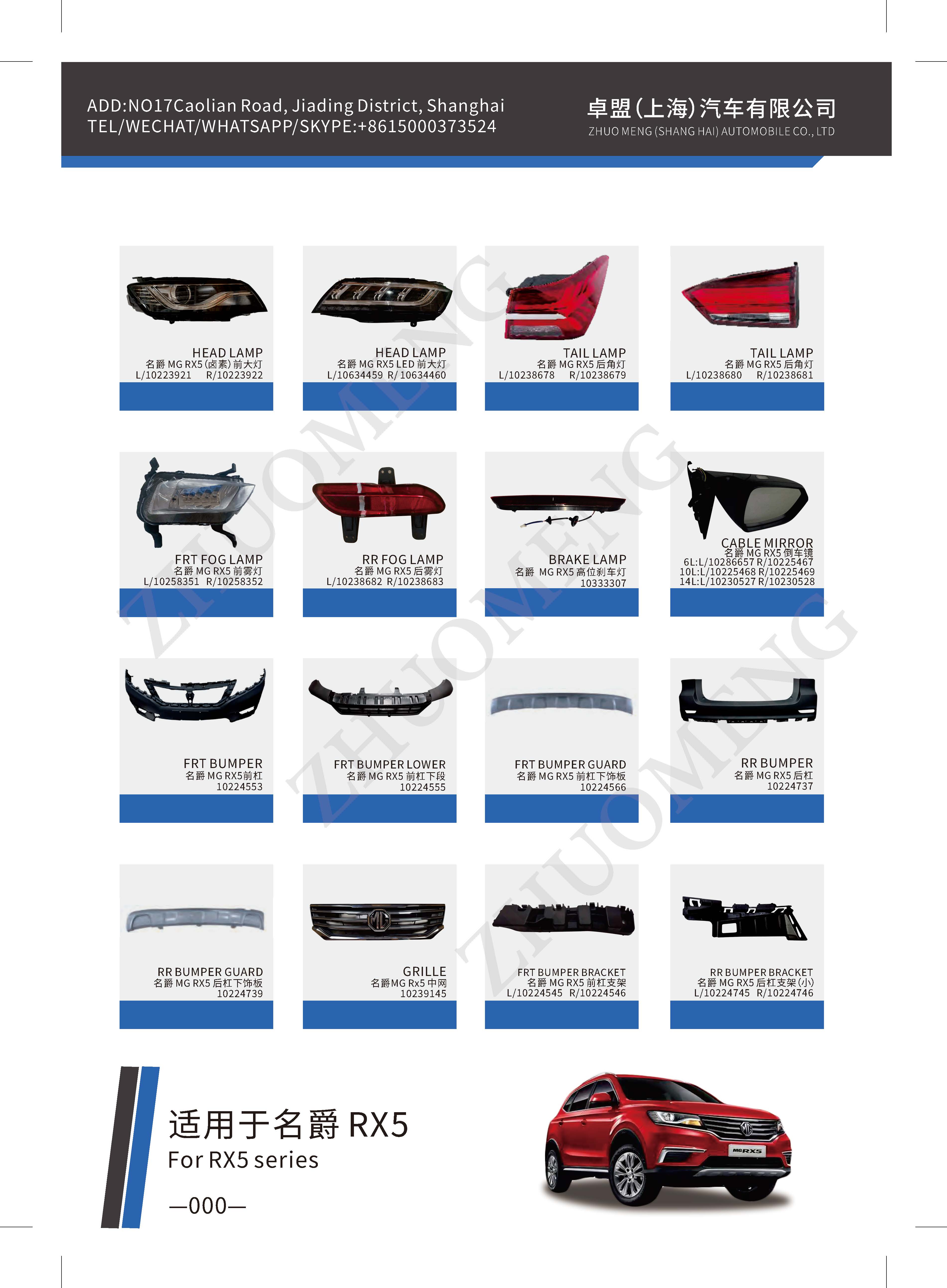

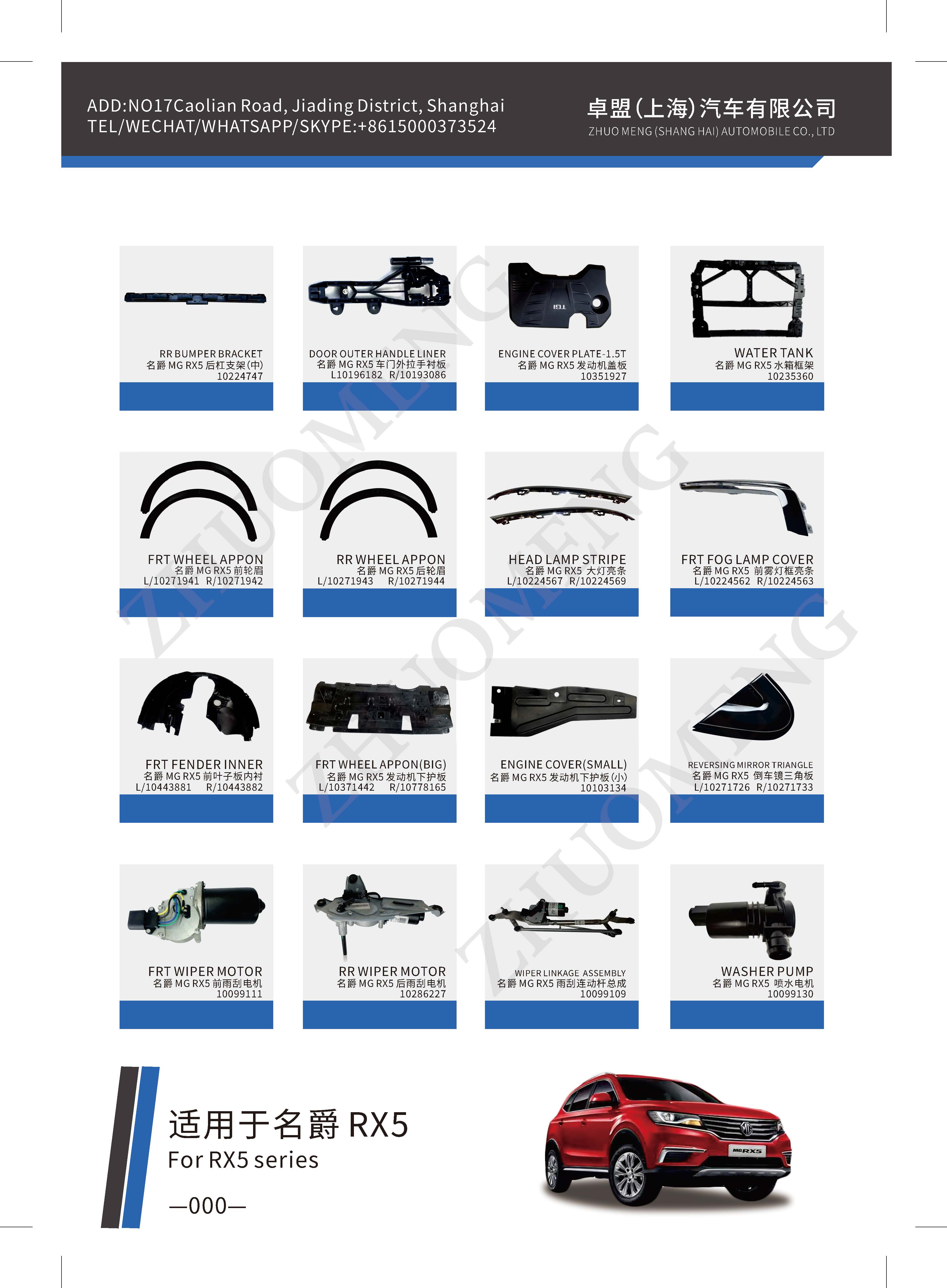

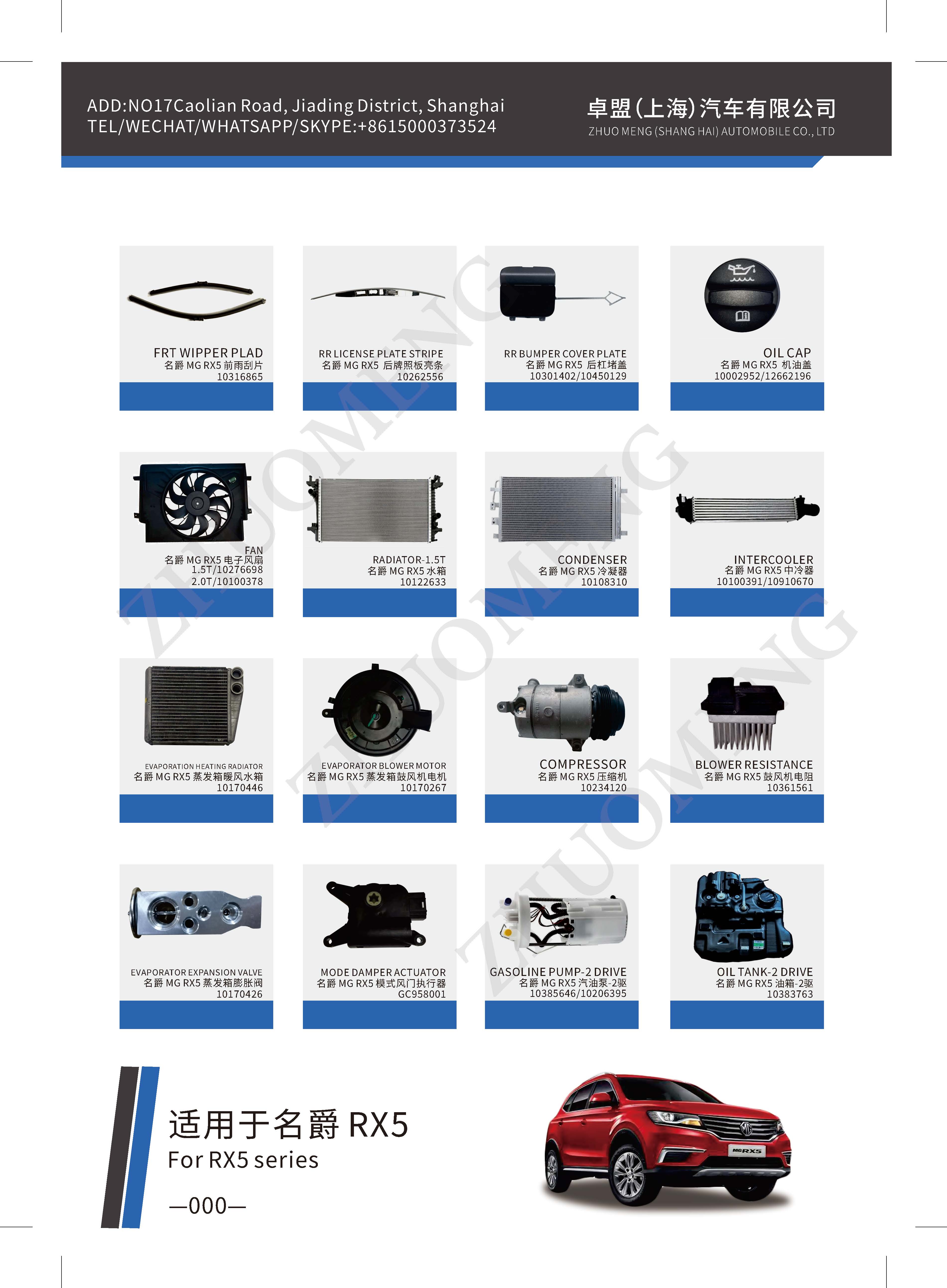

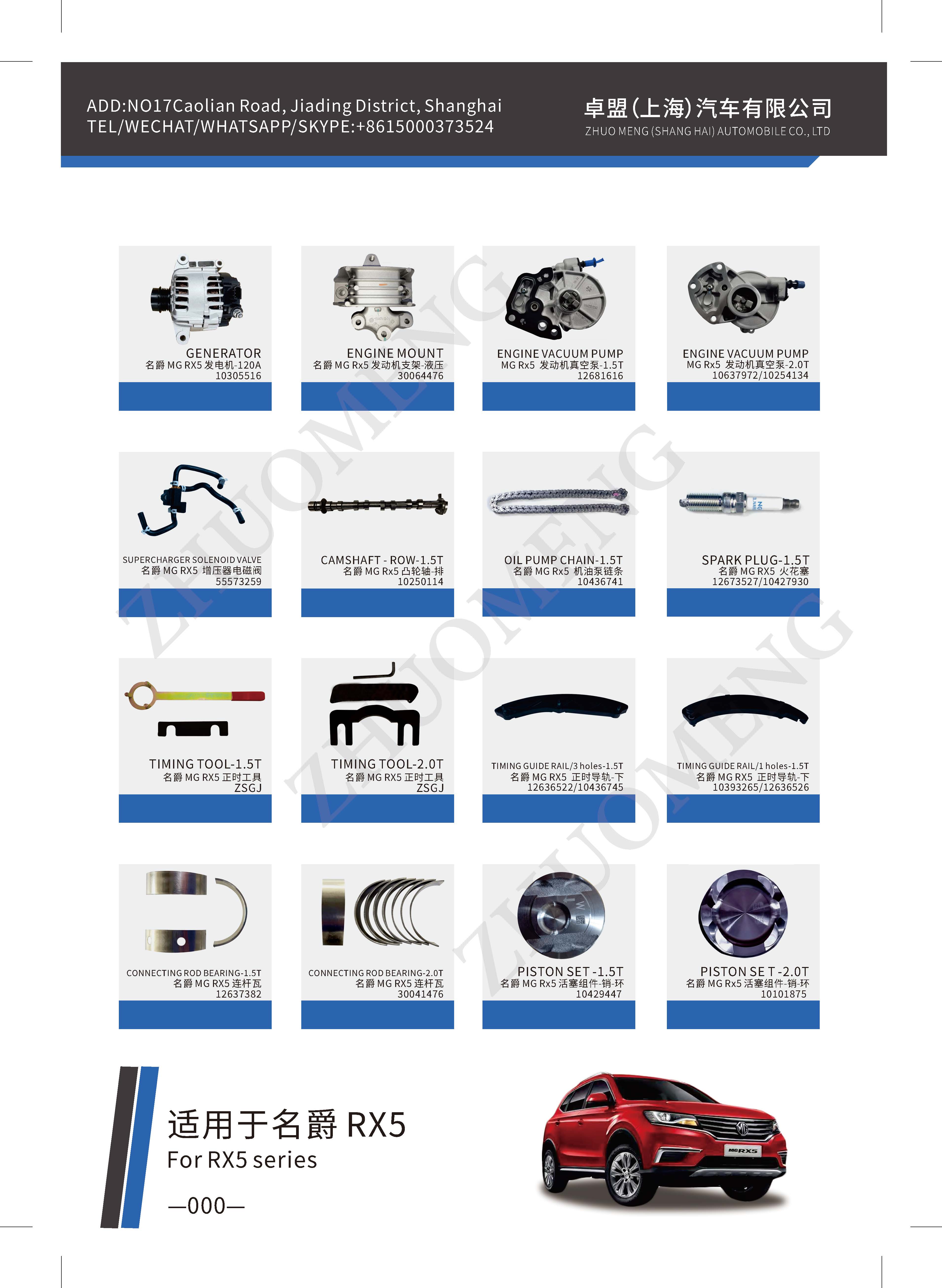

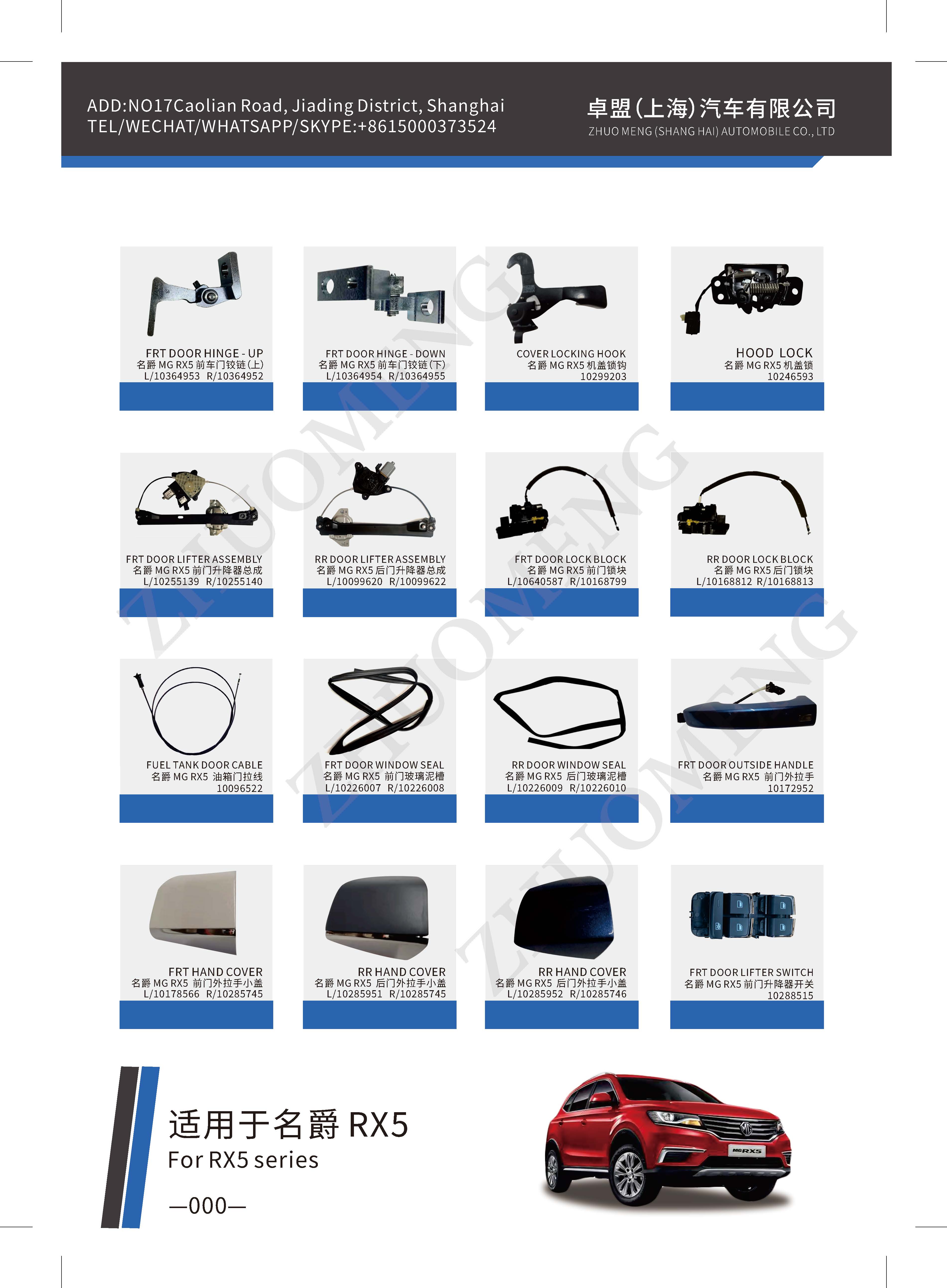

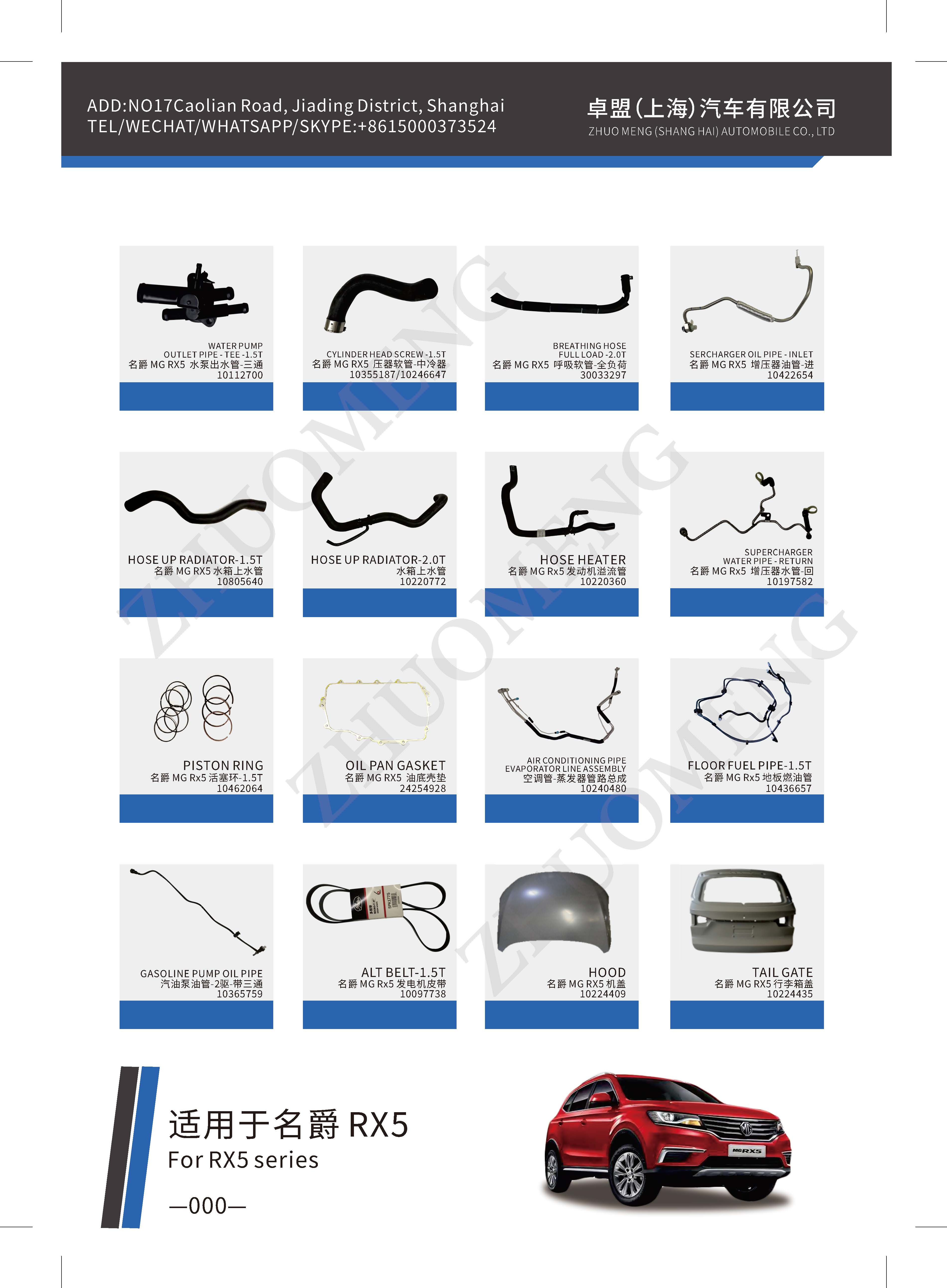

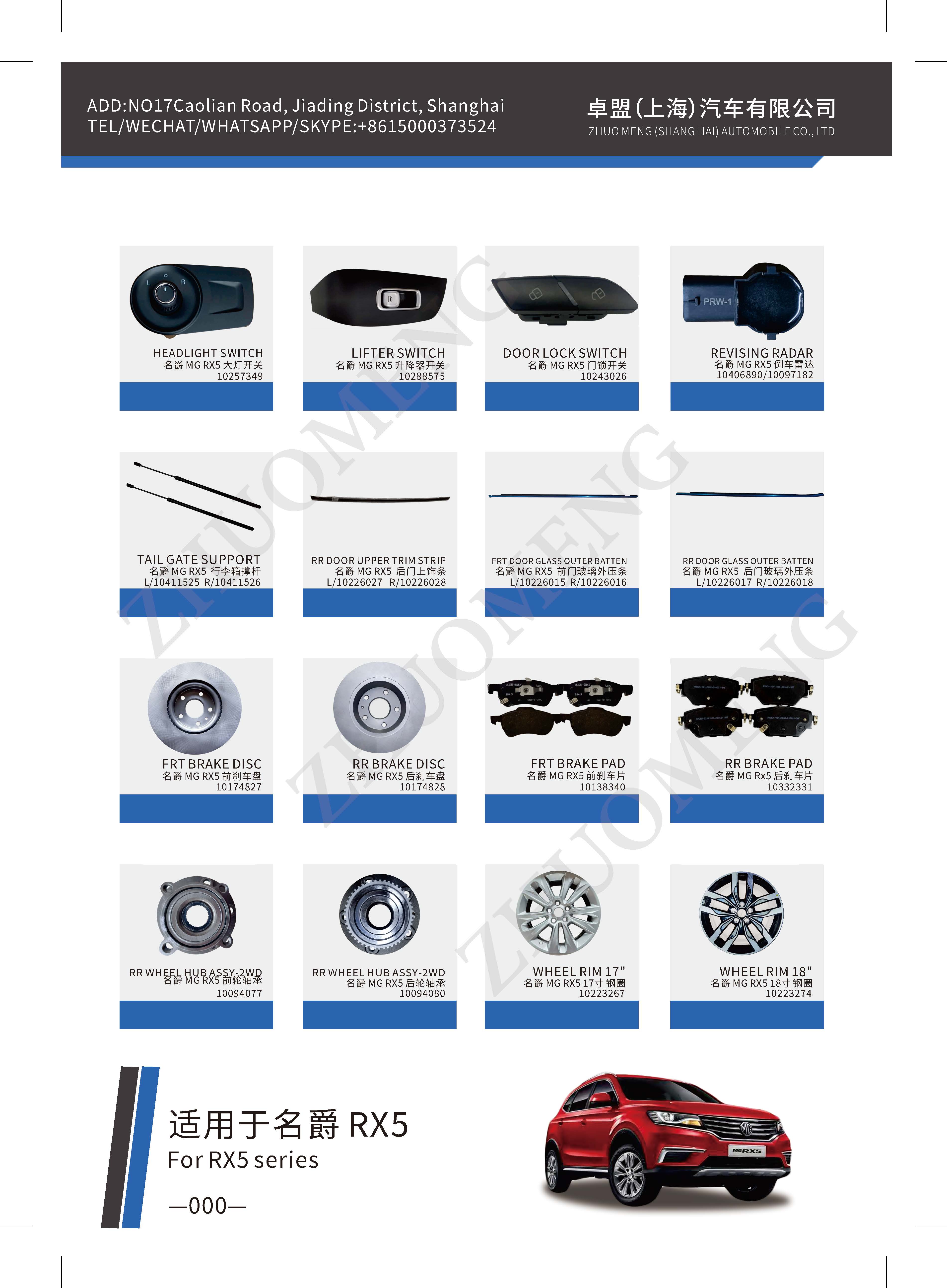

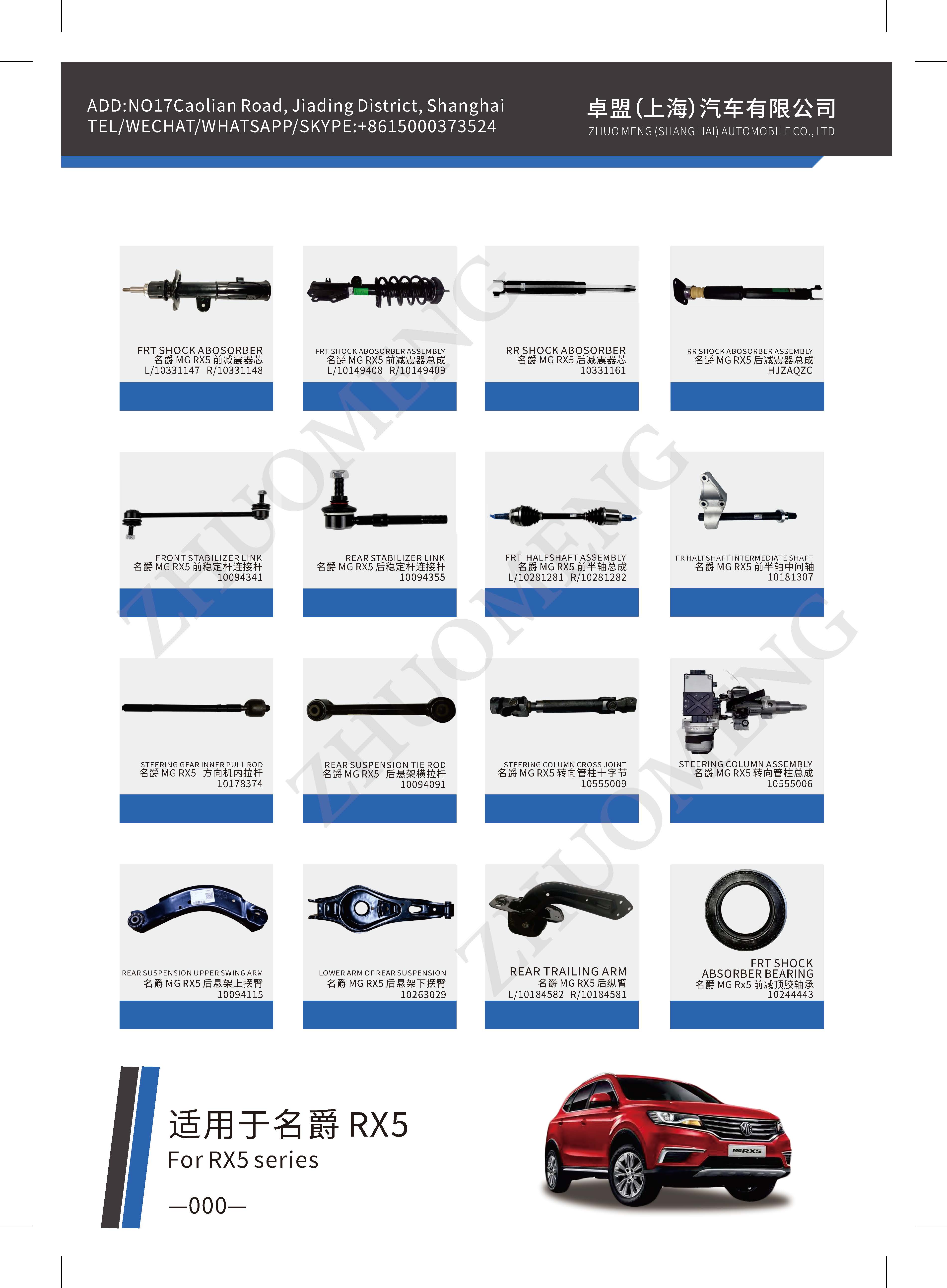

I-atlas yamabheringi ehabhu lezimoto

Ihabhu yezimoto i-Bearing Atlas (amashidi ama-5)

10. Lapho ufaka amantongomane wokukhiya, i-torque iyahluka kakhulu ngenxa yezinhlobo ezihlukene zokuthwala kanye nezihlalo ezithwele.