I-hose ye-radiator yenjini isikhathi eside izoguga, iphuke kalula, amanzi kulula ukungena kurediyetha, ipayipi liphukile ngesikhathi sokushayela, ukuphuma kwamanzi okushisa okuphezulu kuzokwakha iqembu elikhulu lokukhishwa komphunga kusuka kusembozo senjini, lapho lesi simo senzeke, kufanele sikhethe ngokushesha indawo ephephile yokumisa, bese sithatha izinyathelo eziphuthumayo zokuxazulula.

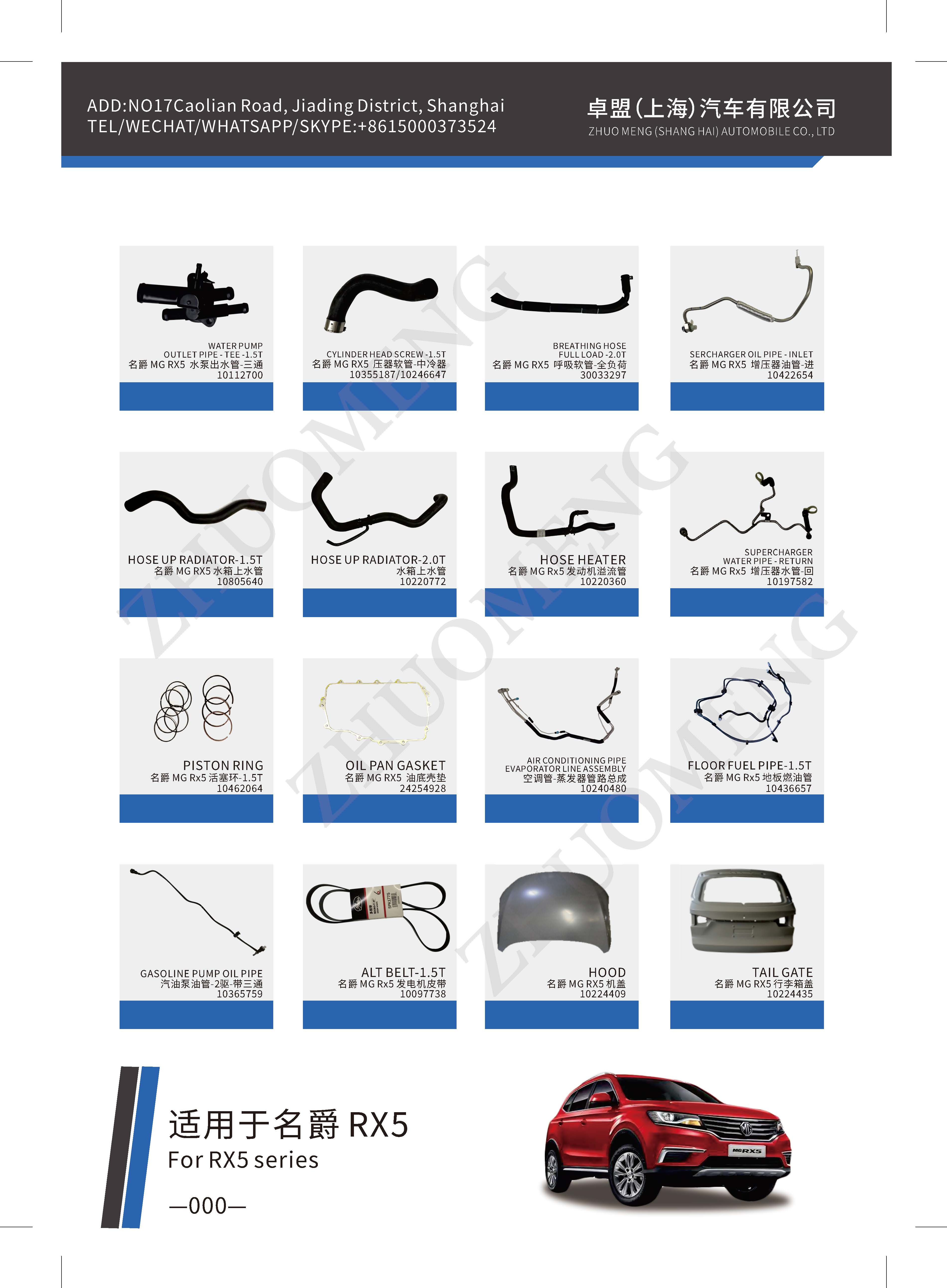

Ngokuvamile, lapho i-radiator isemanzini, ukuhlangana kwe-hose yikhona okungenzeka kakhulu ukukhiqiza imifantu nokuvuza. Ngalesi sikhathi, ungakwazi ukusika ingxenye eyonakele ngesikelo, bese ufaka ipayipi endaweni ehlangene yokufaka irediyetha futhi, bese uyiqinisa ngesiqeshana noma ngocingo. Uma ukuqhekeka kuphakathi nendawo yepayipi, ungasonga ukuqhekeka okuvuzayo nge-tape. Sula ipayipi ngaphambi kokulisonga, bese usonga itheyiphu endaweni evuzayo ngemva kokuba ukuvuza komile. Ngenxa yokuthi ukucindezela kwamanzi ku-hose kuphezulu lapho injini isebenza, i-tape kufanele isongwe ngokuqinile ngangokunokwenzeka. Uma ungenayo iteyiphu esandleni, ungaphinda usonge ngephepha lepulasitiki ekudabukeni kuqala, bese usika indwangu endala ibe yimichilo bese uyigoqa eduze kwepayipi. Ngezinye izikhathi ukuqhekeka kwepayipi kuba kukhulu, futhi kusengase kuvuze ngemva kokubanjwa. Ngalesi sikhathi, ikhava yethangi ingavulwa ukuze kuncishiswe ingcindezi emzileni wamanzi nokunciphisa ukuvuza.

Ngemva kokuba lezi zinyathelo ezingenhla sezithathwe, isivinini senjini akufanele sisheshe kakhulu, futhi kuyadingeka ukulenga ukushayela okusezingeni eliphezulu ngangokunokwenzeka. Ngesikhathi sokushayela, kuyadingeka futhi ukunaka indawo ye-pointer yegeji yokushisa kwamanzi. Uma izinga lokushisa lamanzi liphezulu kakhulu, kuyadingeka ukuthi ume futhi uphole noma wengeze amanzi okupholisa.

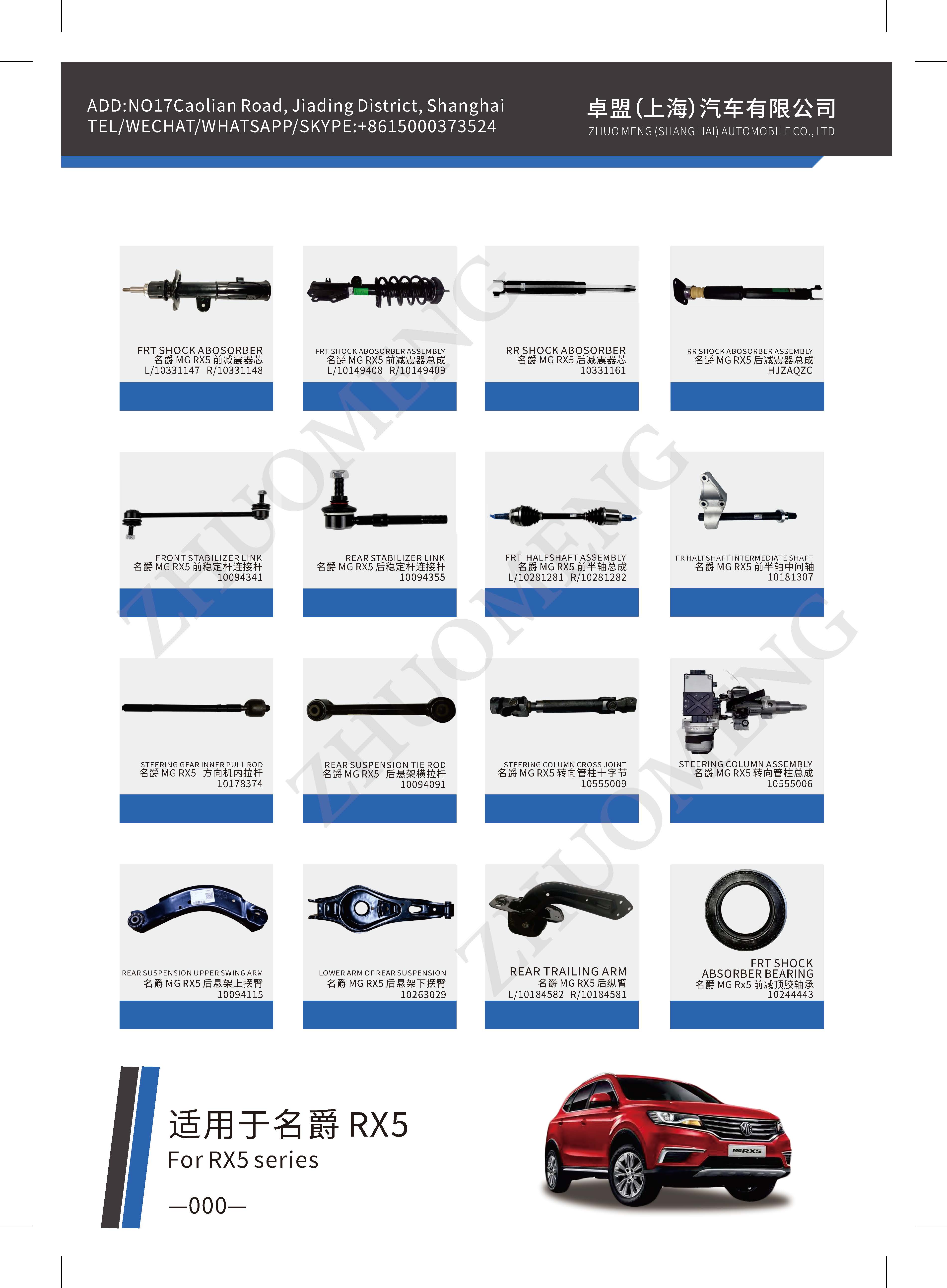

Irediyetha ihlukaniswe yaba izindlela ezintathu zokufaka, njengohlangothi olufanayo phakathi, uhlangothi olufanayo olungaphandle, uhlangothi oluhlukile phakathi, uhlangothi oluhlukile olungaphandle, kanye nephansi ngaphakathi naphansi ngaphandle. Kungakhathaliseki ukuthi iyiphi indlela engasetshenziswa, kufanele sizame ukunciphisa inani lokufakwa kwamapayipi. Ukufakwa kwamapayipi amaningi, hhayi nje izindleko ezizokhula, kodwa futhi nezingozi ezifihliwe zizokhula