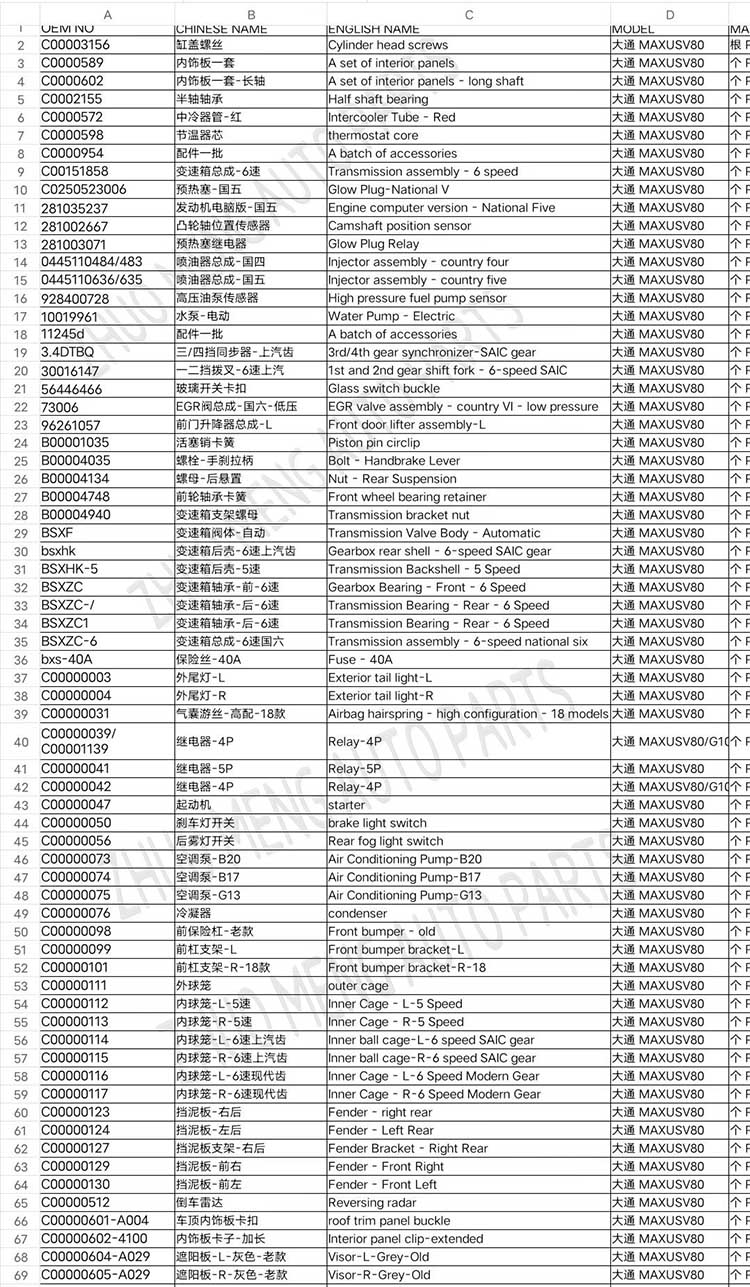

Intengo yefekthri SAIC MAXUS V80 C00014635 Ipani Yamafutha - Country IV

Incazelo emfushane:

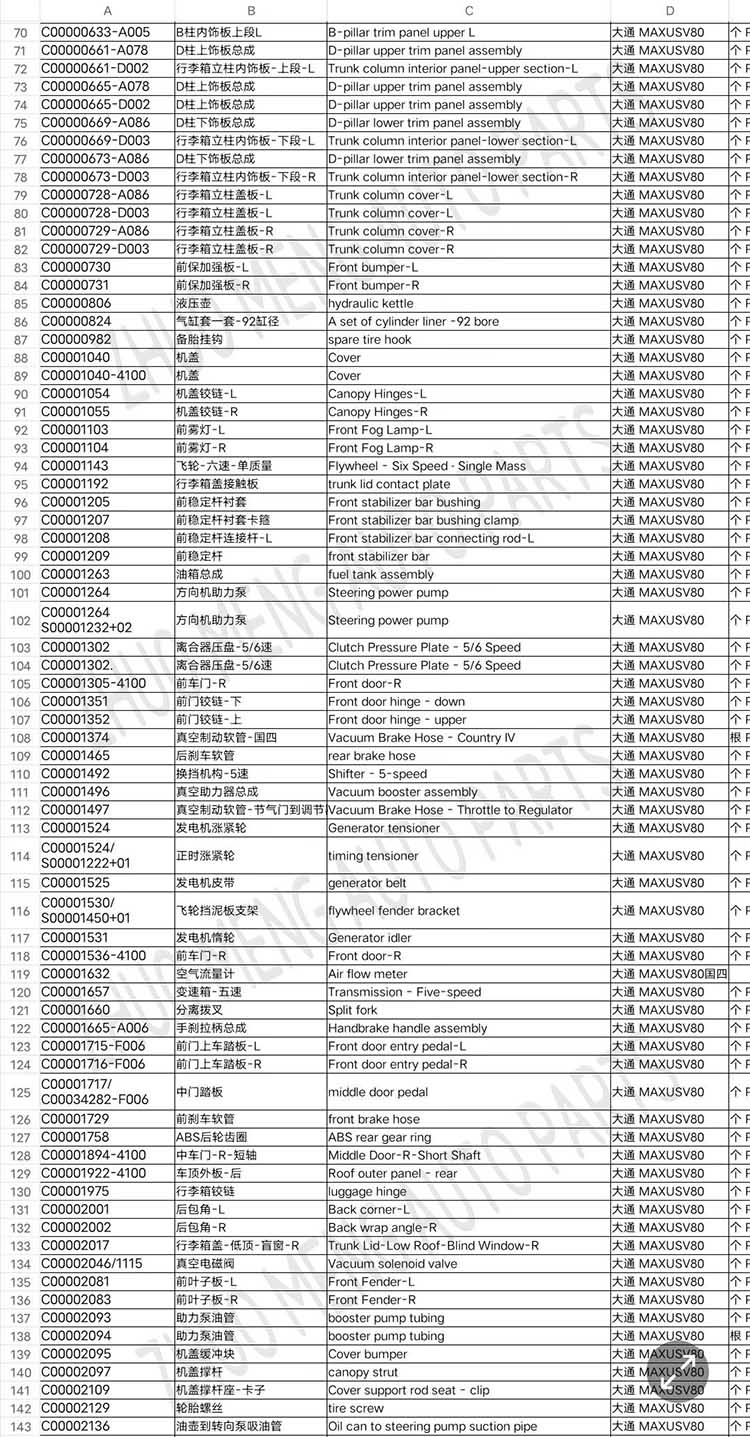

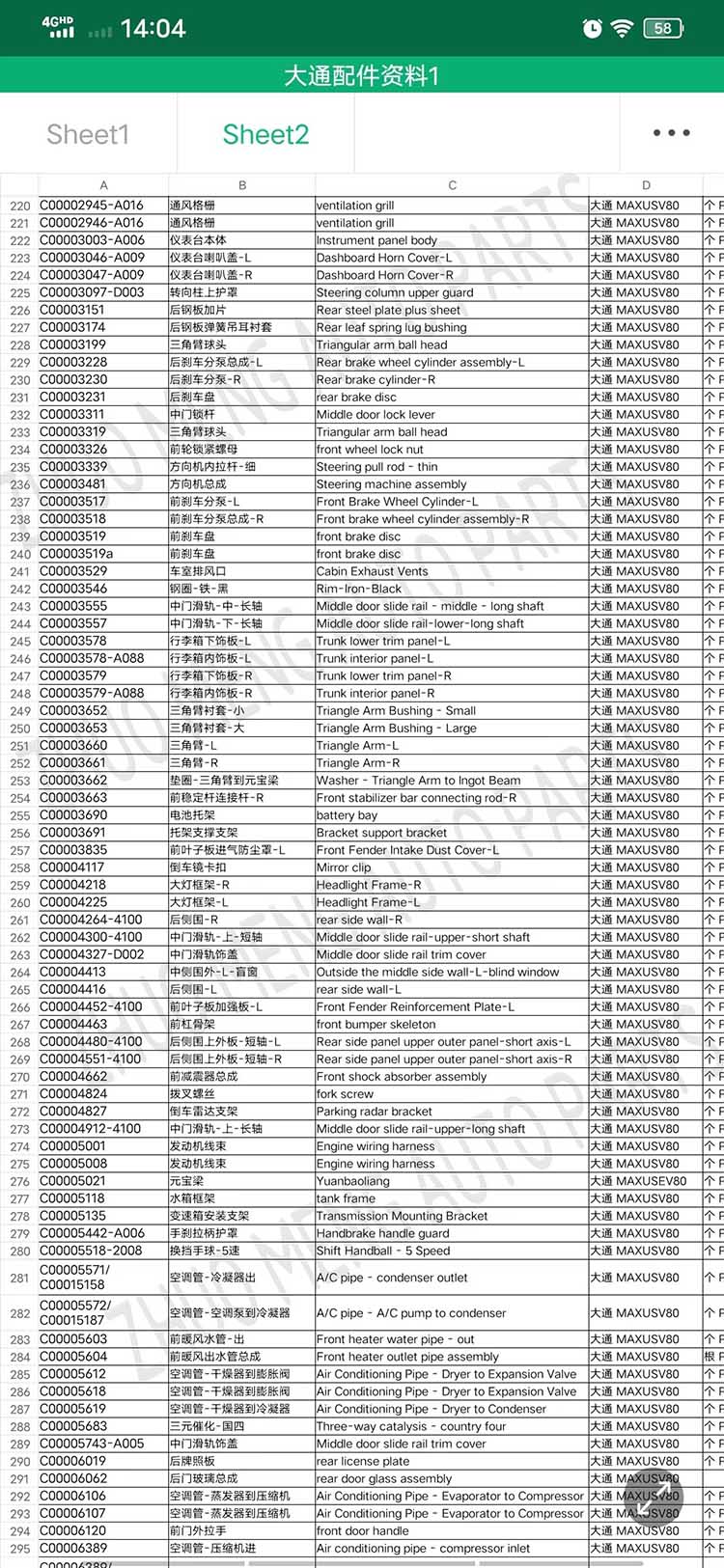

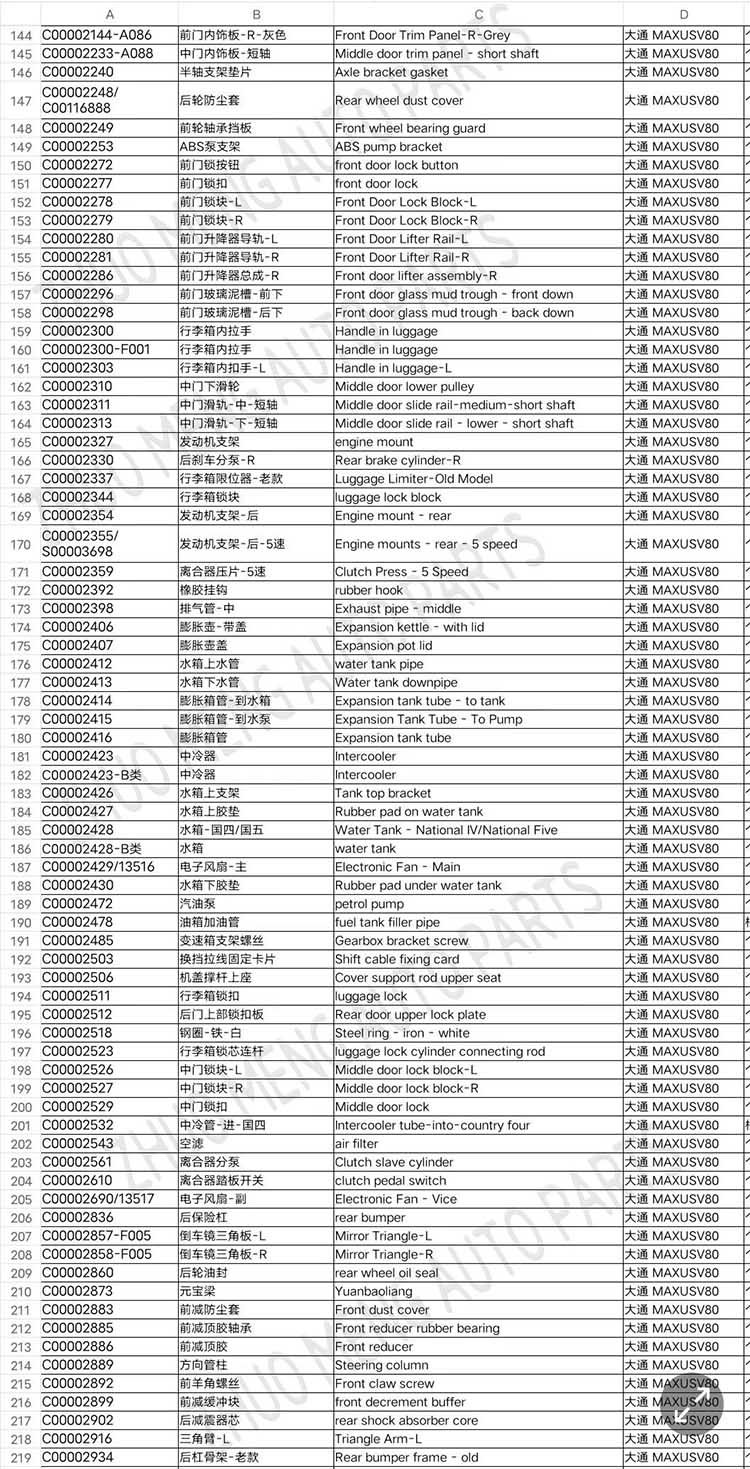

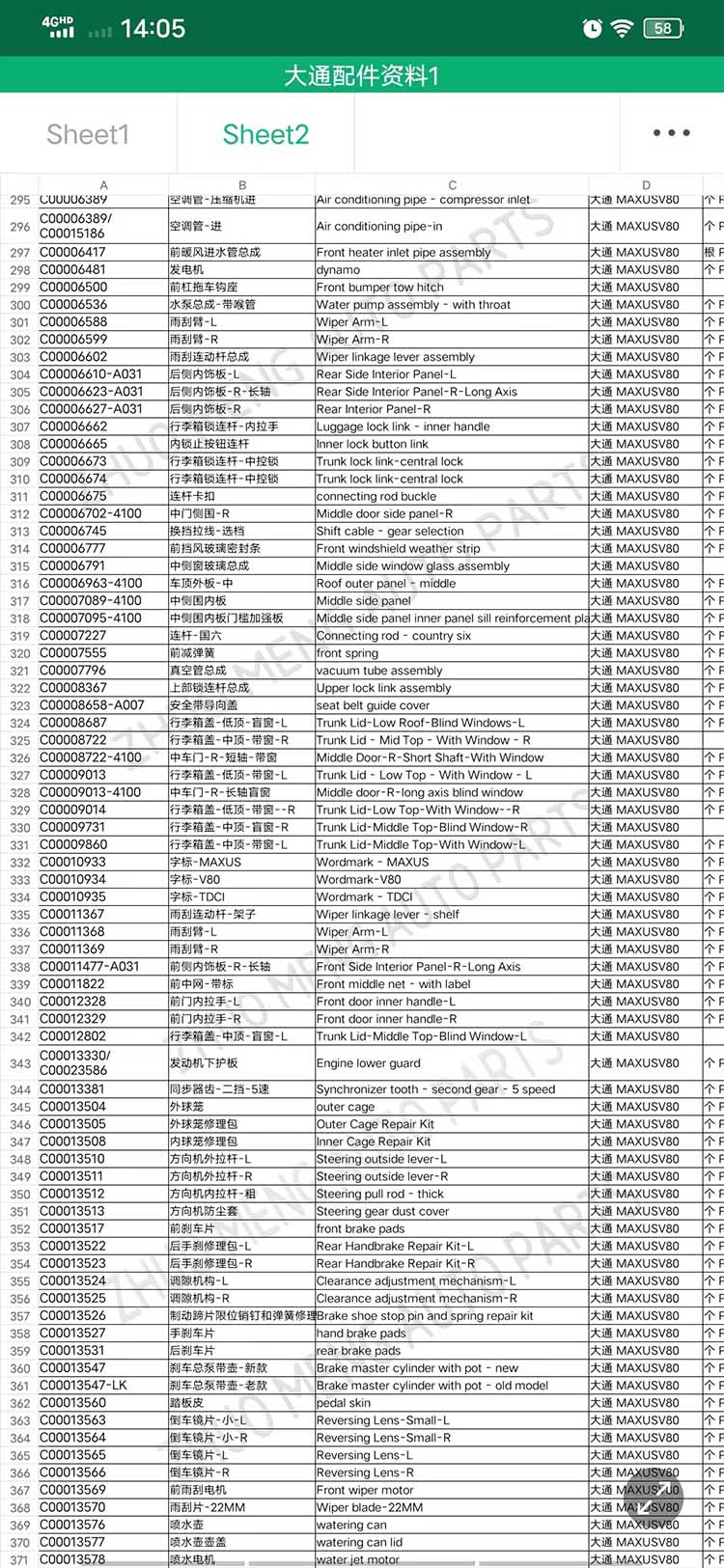

Imininingwane Yomkhiqizo

Omaka bomkhiqizo

Ulwazi lwemikhiqizo

| Igama lemikhiqizo | I-Oil Pan |

| Isicelo semikhiqizo | I-SAIC MAXUS V80 |

| Imikhiqizo ye-OEM NO | C00014635 |

| I-Org yendawo | KWENZIWE ESHAYINA |

| Ibhrendi | I-CSSOT /RMOEM/ORG/COPY |

| Isikhathi esiholayo | Isitoko, uma singaphansi kwama-PCS angama-20, inyanga eyodwa evamile |

| Inkokhelo | Idiphozithi ye-TT |

| Inkampani Brand | CSSOT |

| Uhlelo lokusebenza | Isistimu yamandla |

Ulwazi lwemikhiqizo

manzi

I-Sump Emanzi

ipani lamafutha

Iningi lezimoto ezibonakala emakethe ngamapani kawoyela amanzi. Isizathu esenza aqanjwe ngokuthi amapani kawoyela amanzi ukuthi i-crankshaft crankshaft kanye nesiphetho esikhulu se-rod yokuxhuma injini kucwiliswa emafutheni okugcoba epani likawoyela kanye njalo ukuphenduka kwe-crankshaft. Ngesikhathi esifanayo, ngenxa yokusebenza ngesivinini esiphezulu kwe-crankshaft, isikhathi ngasinye lapho i-crankshaft icwiliswa echibini likawoyela ngesivinini esikhulu, ama-splash athile kawoyela kanye nenkungu kawoyela izovuswa ukuze kugcotshwe i-crankshaft kanye nesihlahla esithwalayo, okubizwa ngokuthi i-splash lubrication. Ngale ndlela, kunezidingo ezithile zezinga le-liquid lamafutha okugcoba epanini likawoyela. Uma iphansi kakhulu, i-crankshaft ye-crankshaft kanye nomkhawulo omkhulu wenduku yokuxhuma ayikwazi ukucwiliswa kumafutha okugcoba, okuholela ekuntulekeni kokuthambisa kanye ne-crankshaft ebushelelezi, induku yokuxhuma kanye nesihlahla esithwalayo. ; Uma izinga likawoyela wokugcoba liphezulu kakhulu, ukuthwala kuzocwiliswa ngokuphelele, okuzokwandisa ukumelana nokujikeleza kwe-crankshaft, okuzogcina kuholele ekwehleni kokusebenza kwenjini.

Lolu hlobo lwendlela yokugcoba lunesakhiwo esilula futhi aludingi ithangi lamafutha elengeziwe, kodwa ukuthambekela kwemoto akufanele kube kukhulu kakhulu, ngaphandle kwalokho kuzodala ingozi ye-cylinder yamafutha evuthayo ngenxa yokwehluleka kwamafutha nokuvuza kwamafutha.

omile

I-Dry Sump

Ama-dry sumps asetshenziswa ezinjinini eziningi zomjaho. Ayigcini uwoyela ku-sump, ngokunembile, akukho sump yamafutha. Ukungqubuzana kwalokhu kunyakaza ku-crankcase kugcotshwa ngokucindezela kuphume uwoyela nge-orifice ngayinye. Njengoba injini eyomile ye-sump ikhansela umsebenzi wokugcina uwoyela we-oyela sump, ukuphakama kwe-sump kawoyela ongahluziwe kuyehla kakhulu, nokuphakama kwenjini nakho kuyancipha. Inzuzo enkulu ukuthi igwema izimo ezingezinhle ze-wet sump ebangelwa ukushayela kakhulu.

Kodwa-ke, yonke ingcindezi yamafutha okugcoba ivela empompini yamafutha. Amandla wephampu kawoyela axhunywe amagiya ngokujikeleza kwe-crankshaft. Nakuba enjinini ye-sump emanzi, ipompo likawoyela liyadingeka ukuze kuhlinzekwe ukucindezela kwe-camshaft. Kodwa lokhu kucindezela kuncane, futhi iphampu kawoyela idinga amandla amancane kakhulu. Ezinjinini ezomile ze-sump, nokho, amandla alokhu kugcotshwa kwengcindezi kumele abe makhulu kakhulu. Futhi usayizi wephampu kawoyela nawo mkhulu kakhulu kunepompo kawoyela yenjini ye-sump emanzi. Ngakho-ke, iphampu kawoyela idinga amandla engeziwe ngalesi sikhathi. Lokhu kufana nenjini eshajwe kakhulu, iphampu kawoyela idinga ukusebenzisa ingxenye yamandla enjini. Ikakhulukazi ngesivinini esikhulu, lapho ijubane lenjini likhuphuka, ukunyakaza kwezingxenye zokungqubuzana kuyanda, futhi kudingeka uwoyela owengeziwe ukuze kugcotshwe, ngakho-ke iphampu kawoyela idinga ukunikeza ingcindezi eyengeziwe, kanye nokusetshenziswa kwamandla ka-crankshaft nakho kuyaqina.

Ngokusobala, umklamo onjalo awufaneleki ezinjini zezimoto zomphakathi ezivamile, ngoba udinga ukulahlekelwa ingxenye yamandla enjini, engathinti kuphela ukuphuma kwamandla, kodwa futhi akusizi ukuthuthukisa umnotho. Ngakho-ke, i-sump eyomile ifakwe kuphela izinjini ezinkulu zokufuduka noma ezinamandla amakhulu, njengalezo zimoto zezemidlalo ezizalelwa ukushayela okukhulu. Isibonelo, i-Lamborghini yamukela umklamo we-sump yamafutha omile. Kulokhu, kubaluleke kakhulu ukuthuthukisa umphumela wokugcoba emkhawulweni futhi uthole isikhungo esiphansi sokudonsela phansi, futhi ukulahlekelwa kwamandla kunganxeshezelwa ngokwandisa ukufuduka nezinye izici. Mayelana nomnotho Ubulili yinto engadingi kucatshangwa nhlobo lo mfuziselo.

Ukusebenza nokugcinwa

Iphampu yomjovo kaphethiloli iyingxenye ebalulekile yesistimu yokunikeza uphethiloli we-diesel generator, futhi isimo sayo sokusebenza sithinta ngokuqondile amandla, umnotho nokuthembeka kwejeneretha ye-diesel. Ukugcinwa okulungile kuyisidingo esibalulekile sokuqinisekisa ukusebenza okuvamile kwephampu yomjovo kaphethiloli futhi kwelule impilo yayo yesevisi. Lezi "elementi eziyishumi" ezilandelayo zikufundisa indlela yokulondoloza iphampu yomjovo kaphethiloli wamajeneretha edizili:

1. Ukugcina kahle izesekeli zephampu yomjovo kaphethiloli.

Isembozo eseceleni somzimba wephampu, i-dipstick kawoyela, ipulaki yokufaka amafutha (i-respirator), ivalvu yokuchitheka kukawoyela, ipulaki yesikulufu sechibi likawoyela, isikulufu sezinga likawoyela, ibhawodi lokulungisa iphampu kawoyela, njll. kufanele igcinwe injalo. Lezi zinsiza zidlala indima ebalulekile ekusebenzeni kwephampu yomjovo kaphethiloli. indima ebalulekile. Isibonelo, isembozo eseceleni singavimbela ukungena kokungcola okunjengothuli namanzi, umshini wokuphefumula (onesihlungi) ungavimbela ngokuphumelelayo ukuwohloka kwamafutha, futhi i-valve yokuchichima kwamafutha iqinisekisa ukuthi uhlelo lukaphethiloli lunokucindezela okuthile futhi alungeni emoyeni. Ngakho-ke, kuyadingeka ukuqinisa ukugcinwa kwalezi zesekeli, futhi uzilungise noma uzishintshe ngesikhathi uma zilimele noma zilahlekile.

2. Njalo hlola ukuthi inani likawoyela kanye nekhwalithi ku-pool kawoyela wephampu yomjovo kaphethiloli kuyahlangabezana yini nezidingo.

Ngaphambi kokuqala ijeneretha ye-diesel, inani kanye nekhwalithi yamafutha empompi yomjovo kaphethiloli kufanele ihlolwe isikhathi ngasinye (ngaphandle kwepompo yomjovo kaphethiloli ephoqeleka ukuba igcotshwe yinjini) ukuze kuqinisekiswe ukuthi inani lamafutha lanele futhi izinga lihle. Uma kungenjalo, kuzodala ukuguga kwangaphambi kwesikhathi kwe-plunger kanye nokubhanqwa kwevalve yokukhipha uwoyela, okuholela emandleni anele enjini kadizili, ubunzima bokuqalisa, futhi ezimeni ezinzima, ukugqwala nokugqwala kwe-plunger kanye nama-valve okukhipha uwoyela. Ngenxa yokuvuza kwangaphakathi kwephampu kawoyela, ukusebenza kabi kwe-valve yokukhipha uwoyela, ukuguga kwe-tappet kanye nembobo yepompo yokudlulisa uwoyela, kanye nokulimala kwendandatho yokuvala, uwoyela wedizili uzovuza echibini likawoyela futhi ahlambulule uwoyela. Ngakho-ke, kufanele ishintshwe ngesikhathi ngokusho kwekhwalithi yamafutha. I-tank ihlanzwa kahle ukuze ikhiphe udaka nokunye ukungcola phansi kwethangi lamafutha, ngaphandle kwalokho amafutha azokonakala ngemva kwesikhathi esifushane sokusetshenziswa. Inani lamafutha akufanele libe liningi kakhulu noma libe lincane kakhulu. Uwoyela omningi kumbusi uzoholela kalula "ekugijimeni" kwenjini ye-diesel. Uwoyela omncane kakhulu uzodala ukuthambisa okungekuhle. I-dipstick kawoyela noma isikulufu sendiza kawoyela sizoba namandla. Ngaphezu kwalokho, lapho injini ye-diesel ingasetshenziswa isikhathi eside, kuyadingeka ukuhlola ukuthi kukhona yini ukungcola okufana namanzi namafutha edizili emafutheni echibini lamafutha lepompo likawoyela. Izingcezu ezigqwalile zabhajwa futhi zalahliwe.

3. Hlola njalo futhi ulungise ukunikezwa kukaphethiloli kwesilinda ngasinye sepompo yomjovo kaphethiloli.

Ngenxa yokuguga kwe-coupler ye-plunger kanye ne-coupler ye-valve yokukhipha uwoyela, ukuvuza kwangaphakathi kukawoyela udizili kuzobangela ukuthi ukunikezwa kukaphethiloli kwesilinda ngasinye kwehliswe noma kungalingani, okuholela ebunzimeni ukuqalisa injini ye-diesel, amandla anganele, ukwanda kokusetshenziswa kukaphethiloli, nokusebenza okungazinzile. Ngakho-ke, kuyadingeka ukuhlola njalo futhi ulungise ukunikezwa kukaphethiloli kwe-cylinder ngayinye yepompo yomjovo kaphethiloli ukuze kuqinisekiswe ukusebenza kwamandla enjini ye-diesel. Ekusetshenzisweni kwangempela, inani likaphethiloli lesilinda ngalinye linganqunywa ngokubheka intuthu ephumayo yejeneretha yedizili, ukulalela umsindo wenjini, nokuthinta izinga lokushisa le-exhaust eningi.

4. Sebenzisa amapayipi kawoyela asezingeni eliphezulu.

Phakathi nenqubo yokunikezwa kukaphethiloli yephampu yokujova uphethiloli, ngenxa yokucindezelwa kukawoyela we-diesel kanye nokunwebeka kwepayipi likawoyela elinomfutho ophezulu, uwoyela we-diesel womfutho ophezulu uzodala ukushintshashintsha kwengcindezi epayipini, futhi kuthatha isikhathi esithile ukuze igagasi lokucindezela lidlulise epayipini. Inani lifana, injini yedizili isebenza kahle, futhi ubude nobubanzi bepayipi likawoyela elinomfutho ophezulu kukhethwa ngemva kokubala. Ngakho-ke, lapho ipayipi likawoyela elinomfutho ophezulu we-cylinder ethile lonakaliswa, ipayipi likawoyela lobude obujwayelekile kanye nobubanzi bepayipi kufanele kushintshwe. Ekusetshenzisweni kwangempela, ngenxa yokuntuleka kwamapayipi kawoyela ajwayelekile, amanye amapayipi kawoyela asetshenziswa esikhundleni salokho, kungakhathaliseki ukuthi ubude nobubanzi bamapayipi kawoyela buyafana, ukuze ubude nobubanzi bamapayipi kawoyela buhluke kakhulu. Nakuba ingasetshenziswa esimweni esiphuthumayo, izoholela ekunikezeni uwoyela we-cylinder. Ukushintsha kwe-engeli esele ngaphambi kwesikhathi kanye nenani lokunikezwa kukawoyela kwenza wonke umshini usebenze ngokungazinzi, ngakho-ke ipayipi likawoyela elisezingeni eliphezulu kufanele lisetshenziswe.

5. Njalo hlola isimo sokuvala i-valve coupler emshinini.

Ngemuva kokuthi ipompo yomjovo kaphethiloli isebenza isikhathi esithile, ngokubheka isimo sokuvala i-valve yokukhipha uphethiloli, kungenziwa isahlulelo esinzima ekugqokeni kwe-plunger kanye nesimo sokusebenza sepompo likaphethiloli, okuzuzisa ukunquma indlela yokulungisa nokulungisa. Uma uhlola, qaqa amapayipi kawoyela anengcindezi ephezulu yesilinda ngasinye, bese usebenzisa iphampu yesandla sikawoyela wephampu yokuletha uwoyela ukumpompa uwoyela. Uma uwoyela egeleza ephuma emajoyintini amapayipi kawoyela phezulu kwepompo yokujova uphethiloli, kusho ukuthi ivalve yokukhipha uwoyela ayivalwanga kahle (yebo, uma isiphethu se-valve yokukhipha uwoyela siphukile, izophinda futhi Uma lokhu kwenzeka), uma kukhona uphawu olubi ku-multi-cylinder, iphampu yomjovo kaphethiloli kufanele ilungiswe kahle futhi igcinwe, futhi i-coupler kufanele ishintshwe.

6. Faka esikhundleni i-plunger egugile kanye ne-valve yokukhipha uwoyela ngesikhathi.

Uma kutholakala ukuthi injini ye-diesel inzima ukuyiqalisa, amandla ayancipha, nokusetshenziswa kukaphethiloli kuyanda, nepompo yokujova uphethiloli nomjovo kaphethiloli namanje akukathuthukisiwe ngokulungisa impompo yokujova uphethiloli, ipuphu yokujova uphethiloli kanye nevalvu yokukhipha uphethiloli kufanele kuhlakazwe futhi kuhlolwe. Uma i-plunger nevalve yokukhipha uphethiloli kugqokwe ngezinga elithile, kufanele kushintshwe ngokuhamba kwesikhathi, ungagcizeleli ukuthi kuphinde kusetshenziswe. Ubunzima bokuqalisa injini ye-diesel, ukwanda kokusetshenziswa kukaphethiloli, amandla anganele kanye nokunye ukulahlekelwa okubangelwa ukuguga kwezingxenye ezihlanganisayo kudlula kude izindleko zokushintsha izingxenye zokuhlanganisa, futhi amandla nomnotho wenjini kadizili izothuthukiswa kakhulu ngemva kokushintshwa. Izingxenye zokushintshwa.

7. Amafutha edizili kufanele asetshenziswe futhi ahlungwe ngendlela efanele ukuze kuqinisekiswe ukuthi amafutha edizili angena empompini yokujova uphethiloli ahlanzeke kakhulu.

Ngokuvamile, amajeneretha edizili anezidingo eziphakeme kakhulu zokuhlunga udizili kunezinjini zikaphethiloli. Amafutha edizili ahlangabezana namabanga adingekayo kufanele akhethelwe ukusetshenziswa, futhi kufanele abe nemvula okungenani amahora angama-48. Qinisa ukuhlanzwa nokugcinwa kwesihlungi sikadizili, hlanza noma shintsha isihlungi ngesikhathi; hlanza ithangi likadizili ngesikhathi ngokwezimo zemvelo yokusebenza, susa kahle udaka kanye nomswakama phansi kwethangi likaphethiloli, futhi noma yikuphi ukungcola okukudizili kuzothinta i-plunger yepompo yokujova uphethiloli kanye nokuphuma kwamafutha. Ukugqwala okukhulu noma ukuguga kwama-valve couplers nezingxenye zokudlulisela.

8. Njalo hlola futhi ulungise i-engeli yokunikezwa kukaphethiloli kusengaphambili yephampu yomjovo kaphethiloli kanye ne-engeli yesikhawu yokunikezwa kukaphethiloli yesilinda ngasinye.

Ngesikhathi sokusetshenziswa, ngenxa yokuxegiswa kwama-coupling bolts kanye nokugqokwa kwe-camshaft kanye nezingxenye zomzimba ze-roller, i-engeli yokuqala yokunikezwa kukawoyela kanye ne-angle yokunikezwa kukawoyela yesikhawu se-cylinder ngayinye kuvame ukuguqulwa, okwenza ukusha kukadizili kube kubi kakhulu, namandla nomnotho wenjini ye-diesel. Ukusebenza kuyancipha, futhi ngesikhathi esifanayo, kunzima ukuqala, ukungazinzi ekusebenzeni, umsindo ongavamile nokushisa ngokweqile. Ekusetshenzisweni kwangempela, abashayeli abaningi banaka ukuhlolwa nokulungiswa kwayo yonke i-engeli yokuphakelwa kukaphethiloli kusengaphambili, kodwa bakushaya indiva ukuhlolwa nokulungiswa kwe-engeli yesikhawu sokuphakelwa kukaphethiloli (okubandakanya ukulungiswa kwe-engeli eyodwa yokuphakelwa kukaphethiloli kwephampu eyodwa). Kodwa-ke, ngenxa yokuguga kwama-camshafts kanye nezingxenye zokudlulisa ama-roller, ukunikezwa kukawoyela kwamasilinda asele akusho ukuthi isikhathi, okuzoholela ebunzimeni bokuqalisa injini ye-diesel, amandla anganele, nokusebenza okungazinzile, ikakhulukazi ipompo yomjovo kaphethiloli osekuyisikhathi eside isetshenziswa. Kuthiwa kufanele kubhekwe kakhulu ekuhlolweni nasekulungisweni kwe-engeli yokunikezwa kukawoyela yesikhawu.

9. Ukuhlola njalo imvume ye-camshaft.

I-axial clearance ye-camshaft yepompo yomjovo kaphethiloli iqinile kakhulu, ngokuvamile iphakathi kuka-0.03 no-0.15mm. Uma imvume inkulu kakhulu, izokwandisa umthelela wezingxenye zokudlulisa i-roller endaweni yokusebenza yekhamera, ngaleyo ndlela kwandise ukuguga kwangaphambi kwesikhathi kwendawo yekhamera futhi kushintshe ukunikezwa. I-oil advance angle; I-camshaft ephethe i-shaft kanye ne-radial clearance inkulu kakhulu, okulula ukubangela ukuthi i-camshaft isebenze ngokungalingani, i-lever yokulungiswa kwevolumu kawoyela iyazamazama, futhi umthamo wokunikezwa kwamafutha ushintsha ngezikhathi ezithile, okwenza injini ye-diesel isebenze ingazinzile, ngakho-ke kuyadingeka ukuhlola nokulungisa njalo. Lapho imvume ye-axial ye-camshaft inkulu kakhulu, ama-shims angangezwa ezinhlangothini zombili ukuze alungiswe. Uma i-radial clearance inkulu kakhulu, ngokuvamile kuyadingeka ukuthi kushintshwe umkhiqizo omusha.

10. Njalo hlola ukuguga kwezikhiye ezifanele namabhawodi okulungisa.

Okhiye abafanelekile namabhawodi ikakhulukazi abhekisela kokhiye be-camshaft, okhiye abaxhumanisayo be-flange (amaphampu kawoyela adlulisa amandla ngama-coupling), okhiye abayi-semicircular namabhawodi okulungisa ahlanganisayo. Ukhiye we-camshaft, ukhiye we-flange kanye nokhiye we-semicircular wepompo yokujova uphethiloli sekusetshenziswe isikhathi eside, futhi izibani zigugile, okwenza ukhiye ube banzi, ukhiye we-semicircular awufakiwe ngokuqinile, futhi i-angle yangaphambili yokunikezwa kwamafutha iyashintsha; esimweni esibucayi, ukhiye uyaginqa, okuholela ekuhlulekeni kokudluliswa kwamandla. , ngakho-ke kuyadingeka ukuhlola njalo futhi ulungise noma ushintshe izingxenye ezigugile ngesikhathi.

Izinyathelo zokuzivikela

Izikhuthazi zikadizili

1. I-O-ring yomjovo yonakele;

2. I-atomization engalungile yomjovo, amafutha aconsayo;

3. Ukufakwa okungafanele komjovo;

4. I-O-ring ayizange ishintshwe lapho umjovo ufakwa kabusha.

Isitoreji se-Cummins generator kufanele sinake:

1) Indawo yokugcina ithangi likaphethiloli kumele ivikeleke ukuvikela umlilo. Ithangi likaphethiloli noma isigubhu sikawoyela kufanele kubekwe endaweni ebonakalayo yodwa, kude ngokufanele nesethi yejeneretha yedizili, futhi akuvunyelwe ngokuphelele ukubhema.

2) Umthamo wamafutha ethangini likaphethiloli kufanele uqinisekise ukutholakala kwansuku zonke.

3) Ngemva kokuba ithangi likawoyela libekwe, izinga eliphezulu likawoyela alikwazi ukuba ngaphezu kwamamitha angu-2.5 ngaphezu kwesisekelo sesethi yejeneretha yedizili. Uma izinga likawoyela ledepho enkulu kawoyela lingaphezu kwamamitha angu-2.5, ithangi likawoyela lansuku zonke kufanele lengezwe phakathi kwedepho enkulu kawoyela neyunithi ukuze kwenziwe ingcindezi yokulethwa kukawoyela okuqondile. Angabi ngaphezu kwamamitha angu-2.5. Ngisho nalapho injini ye-diesel icishiwe, uphethiloli awuvunyelwe ukugeleza enjinini kadizili ngolayini ongenisa uphethiloli noma ulayini wokujova uphethiloli ngamandla adonsela phansi.

4) Ukumelana esikhungweni sikawoyela akuvunyelwe ukweqa inani elishiwo kuwo wonke amashidi edatha yokusebenza kwenjini ye-diesel uma usebenzisa isici sokuhlunga esihlanzekile. Leli nani lokumelana lisekelwe engxenyeni kaphethiloli ethangini likaphethiloli.

5) Ukumelana nokubuyiselwa kukaphethiloli akumele kweqe okubekiwe eshidini ledatha yokusebenza kwenjini kadizili esetshenzisiwe.

6) Ukuxhunywa kwepayipi likawoyela obuyayo akumele kubangele amagagasi okwethuka abonakale epayipini likawoyela kawoyela.

UMBONISO WETHU

Imikhiqizo ehlobene

Imikhiqizo ehlobene

-

I-SAIC MAXUS V80 Irediyetha kawoyela - amanzi ensimbi ...

-

Ikhava yekholomu yomboko ohlangothini lwesobunxele lwe-SAIC MA...

-

intengo yefekthri SAIC MAXUS V80 C0004463 ibhamu yangaphambili...

-

I-SAIC MAXUS V80 C00001524 Igenerator Tensioner

-

intengo yefekthri SAIC MAXUS V80 C00014659 Glow Plu...

-

I-MAXUS AUTO PARTS SUPPLIER I-SAIC MAXUS V80 ixhumekile...